Company philosophy

To be one of the most top competitor in the field of mold and die fabrication.

To improve more for the better quality of work and for the satisfaction of customer's demand.

We are engaged in manufacturing of mold and dies consisting of three Japanese on Technical Guidance and 43 Filipino Engineers under Production Manpower.

We have expanded over machineries and tools year by year.

This 2019, our goal is to produce at least 20 molds per month.

Product line

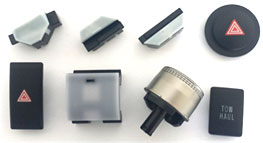

Mechanism parts and appearance parts and two-color molding die and manufacturing of insert mold.

We widely accept projects for automotive parts, printer parts and connector parts.

Mold

We are flexible to fit the mold specification of each manufactures for up to 280T size injection mold.

Mechanism parts mold

Insert injection mold

Double injection mold

Factory / Equipment

Design Equipment

| 2D CAD | MY PAC 6 units / CAM-TOOL HYBRID 5 units | |

| 3D CAD/CAM | CIMATRON 1 unit / CAM-TOOL PARTS 5 units / SOLID WORKS 1 unit |

Processing Equipment

| NAME | QTY | MAKER |

| MACHINING CENTER | 4 | MAKINO PS65 (2) / F3 (3) |

| CNC MACHINE | 2 | SHIZUOKA AN-SRN |

| WIRE-CUT EDM | 4 | SODICK SL400G (2) / AG400L (1) / VZ500L (1) |

| EDM | 4 | SODICK AD35L (4)/ AD30L (1) |

| SUPER DRILL | 1 | SODICK K1C |

| MILLING MACHINE | 5 | OKUMA / SHIZUOKA/ BENIGN |

| SURFACE GRINDER | 2 | SODICK ACC 63DX / ACC 64DX |

| FORMING GRIND | 4 | OKAMOTO ACC-350 II |

| FORMING GRIND | 1 | NICCO NSG-550B |

| LATHE MACHINE | 1 | YAM YANG CL4070AG |

| RADIAL DRILLING MACHINE | 1 | YODOGAWA TK-125HVS |

| METAL CUTTING BAND SAW | 1 | VERTEX HBS7 |

| LASER WELDING | 1 | ROFIN |

| CNCCMM | 1 | MITUTOYO |

| VISUAL MICROSCOPE | 5 | CARTON NSZ |

| MICROSCOPE | 1 | MITUTOYO MF-A2017D |

Measurement Equipment

| Microscope | MITSUTOYO MF-A2017D (1) |

| CMM(NC) | MITSUTOYO 544(1) |